Powder coating on pultrusion components is commonly found in buildings like bridges, handrails, and offshore platforms, the place sturdiness and longevity are paramount.

You should use a standard oven to powder coat scaled-down objects. Just make certain that you won't be utilizing the oven to Cook dinner foodstuff after the powder coating. When you've used an oven to powder coat, it Totally should not be used for cooking.

Tend not to contact the thing when it is actually faraway from the oven just after curing right up until it is comprehensively cooled.

This technique, specifically common in powder coating, provides several programs demanding precision and procedure. Partial curing emerges as a pivotal system, facilitating optimum crosslinking and adhesion involving the coats.

Infrared (IR) Ovens: IR ovens use gas or electric power as an Vitality resource to emit radiation from the IR wavelength band. This radiation is absorbed through the powder as well as substrate straight beneath the powder with out significantly heating your complete component.

You can also coat metals for example brass, copper, bronze and so on. to prevent them from oxidation. You can also powder coat stainless steel to improve the rust resistance on the metal alloy.

In order to powder coat some thing, clear away all of its threaded or lubricated surfaces so they don't get locked in place. Then, use abrasive blasting to scrub off any rust, Filth, and overseas components.

As a result, components that may be handled by hand need to possess a texture that prevents slipping, but pieces that are meant to Possess a sleek end can perform Therefore if slip-resistance isn't needed.

Several purposes call for a easy floor end, although the orange peel effect is appealing in some purposes. This influence hides metal defects and renders the finished surface area much less liable to showing fingerprints, the two of which can be attractive in unique apps.

Having said that, situations that need colour retention and longevity will frequently opt for fluoropolymer coatings over polyester despite the former currently being dearer. Fluoropolymers excel in preserving color vibrancy eventually and can endure prolonged publicity to ultraviolet rays without fading, producing them perfect for applications wherever aesthetic attractiveness is essential.

These difficulties can hold off project timelines, resulting in elevated expenses which ultimately impacts the overall feasibility and achievement of a challenge.

Following coating, curing will take area – This is certainly mostly reached by means of large warmth. Sometimes, the metallic component is heated ahead of powder software.

When picking a powder coat, it is critical to take into consideration extra than simply the colour; the finish type and texture also Enjoy a crucial role in the ultimate glimpse. For instance, powder coatings can be found in differing types for example gloss, semi-gloss, and matte, which impact the shininess from the coated component.

A rinse phase is typically involved between Just about every pretreatment stage to eliminate any residual chemical substances and contaminants. Finally, a RO (Reverse Osmosis) las vegas powder coating or DI (Deionization) Rinse is applied to improve coating overall performance and lessen pretreatment chemical use.

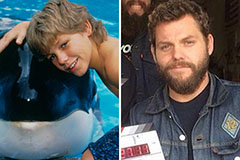

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now!